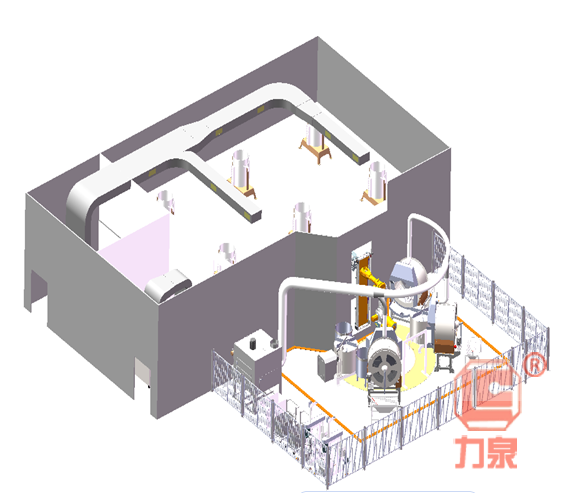

Robot shell workstation system

Robot shell workstation system

Robot shell workstation system

- Detail

- Parameters

Robot shell workstation system

Product Photograph:

Product features:

1. The workstation can automatically grab a whole series of modules from a special trolley or suspension chain, and automatically complete the whole shell-making process of staining, slurry control, hanging sand and returning to a special trolley or suspension chain.

2. The background preprogrammed technology is realized, and the robot automatically identifies the state of the module and seamlessly joins the module according to the preprogrammed program. It completely replaced the traditional artificial shell operation process, eliminating the over reliance on the operator's professional skills.

3. Robot is the core of the shell making process. The operator only needs to do some auxiliary work. The loading capacity of robot 180 kg is far greater than that of manual lifting, which can greatly increase the number of singlestring module assembly welding, greatly increase the yield of process, improve work efficiency and reduce production costs.

4. The doubleloop design of monitoring, emergency stop and fault protection and the threebit starting device make the operation safer, more stable and more reliable.

5. According to the needs of the site, the system can be extended to meet different product and process requirements; at the same time, it also has management and statistical functions, docking with MES system, to complete fine manufacturing control for enterprises, to help enterprises reduce costs, improve product quality and service quality.

面层干燥间

背层干燥间专用旋风塔

工作站操作系统